Manual Ball Valve Manufacturers / Suppliers

VIR brass ball valves, VIR Manual ball valves, 3 piece manual ball valves, Manual and Automated Ball Valves, American made Manual ball valves Suppliers in India

All Types Manual Ball Valves Suppliers, All Size Manual Ball Valves Suppliers in India, All Top Brands Manual Ball Valves Dealer in India, Hastelloy C Manual Ball Valves, Monel Manual Ball Valves, Carbon Steel Manual Ball Valves, Stainless Steel Manual Ball Valves, Alloy Steel Manual Ball Valves.

Manual Ball Valves Suppliers Dealers Distributors Exporters in India

Citizen Valves has extensive experience in manufacturing Trunnion Mounted, Side & Top Entry Ball Valves, both Soft and Metal Seated.

VIR Brand Manual Ball Valve Dealers in India

3 Piece Manual Ball Valve - Series 55

Triac Series 55 Ball Valves feature a high quality investment cast body and ends. They are available 1/4" - 4" with threaded, socket weld and butt weld ends. Superior leak protection is accomplished by using a live-loaded packing system including Bellville washers and double "V" ring packing.

3 Piece Manual Ball Valve Features:

- Sizes 1/4" - 4"

- Economical

- Full Port

- ISO 5211 Mounting Pad

- 800 & 1000 PSI WOG (by size)

- Available 316 SS or WCB

Also Available in an Automated Ball Valve Package

The Series 55 3 Piece Manual Ball Valves are also available with a Pneumatic Spring Return Actuator, Double Acting Actuator or Electric Actuator.

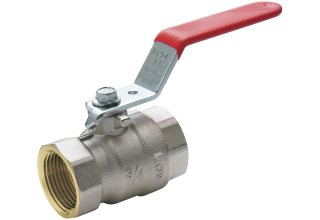

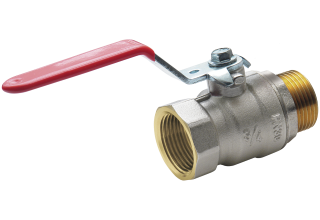

Manual Ball Valves - Fig. 340

Full bore brass ball valve

Diameters from DN008 - ¼" to DN100 - 4"

Threaded F/F (ISO 228/1)

Design according to MSS-SP-110

Air testing according to EN12266-1

Blow-out proof stem, adjustable packing

With handle or butterfly (up to DN≤50)

ACS, VA and TR CU 010 compliant

PN40 for DN≤50 (Max 40bar up to 95°C, max 25bar at 150°C)

PN25 for DN≥65 (Max 25bar up to 95°C, max 16bar at 150°C)

Free of CE marking for DN≤32 (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +150°C

● Suitable for: air, -10°C to +150°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

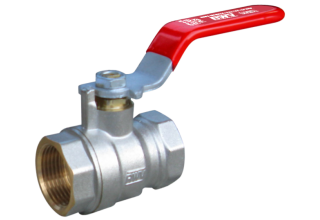

Manual Ball Valves - Fig. 343

Full bore brass ball valve

Diameters from DN008 - ¼" to DN050 - 2"

Threaded M/F (ISO 228/1)

Design according to MSS-SP-110

Air testing according to EN12266-1

Blow-out proof stem, adjustable packing

With handle or butterfly

ACS, VA and TR CU 010 compliant

PN40 (Max 40bar up to 95°C, max 25bar at 150°C)

Free of CE marking for DN≤32 (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +150°C

● Suitable for: air, -10°C to +150°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

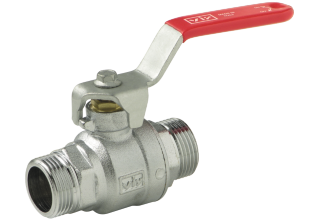

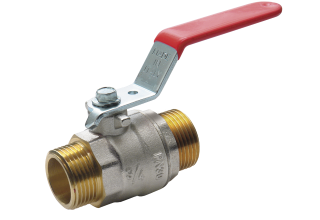

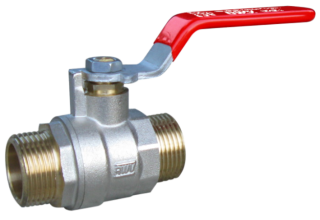

Manual Ball Valves - Fig. 348

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN050 - 2"

Threaded M/M (ISO 228/1)

Design according to MSS-SP-110

Air testing according to EN12266-1

Blow-out proof stem, adjustable packing

With handle or butterfly (up to DN≤50)

ACS, VA and TR CU 010 compliant

PN40 (Max 40bar up to 95°C, max 25bar at 150°C)

Free of CE marking for DN≤32 (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +150°C

● Suitable for: air, -10°C to +150°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

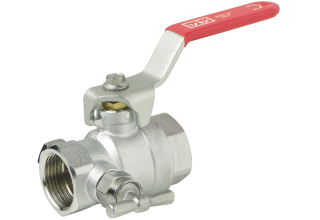

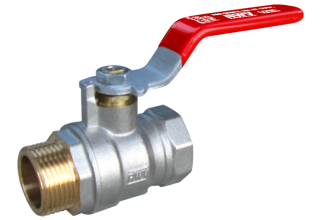

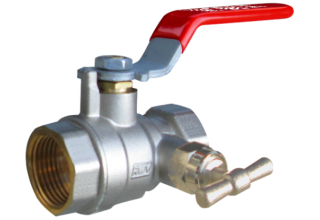

Manual Ball Valves - Fig. 342

Full bore brass ball valve with drain

Diameters from DN015 - ½" to DN050 - 2"

Threaded M/M (ISO 228/1)

Design according to MSS-SP-110

Air testing according to EN12266-1

Blow-out proof stem, adjustable packing

With handle or butterfly

ACS, VA and TR CU 010 compliant

PN40 (Max 40bar up to 95°C, max 25bar at 150°C)

Free of CE marking for DN≤32 (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +150°C

● Suitable for: air, -10°C to +150°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 340 Solar

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN050 - 2"

Threaded F/F (ISO 228/1)

Design according to MSS-SP110

Air testing according to EN12266-1

Seats and packing specific for high temperatures

(Seats in PTFE+graphite, packing in Grafoil)

Blow-out proof stem, adjustable packing

With handle or butterfly (up to DN≤50)

TR CU 010 compliant

PN25 (Max 25bar up to 100°C (75°C for DN50), max 10bar at 180°C)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, -30°C to +180°C

below 0°C only for water with added antifreeze fluids

over 100°C only for water with added anti-boiling fluids

● Not suitable for: gases group 1 & 2, liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 340DR

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN050 - 2"

Threaded F/F (ISO 228/1)

Design according to MSS-SP-110

Air testing according to EN12266-1

Blow-out proof stem

Adjustable packing

CE, VA and STF compliant

PN40 (Max 40bar up to 95°C, max 25bar at 150°C)

PN25 for STF compliant version

Working conditions

● Water: 0°C to +150°C

● Air: -10°C to +150°C

Manual Ball Valves - Fig. 33FF

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN50 - 2"

Threaded F/F (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

Reversible handle

TR CU 010 compliant

PN30 (Max 30bar up to 90°C, max 10bar at 130°C)

When used with air Max 20bar up to 110°C, max 10bar at 130°C

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +130°C

● Suitable for: air, -10°C to +130°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 33MF

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN50 - 2"

Threaded M/F (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

Reversible handle

TR CU 010 compliant

PN30 (Max 30bar up to 90°C, max 10bar at 130°C)

When used with air Max 20bar up to 110°C, max 10bar at 130°C

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +130°C

● Suitable for: air, -10°C to +130°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 33MM

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN25 - 1"

Threaded M/M (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

Reversible handle

TR CU 010 compliant

PN30 (Max 30bar up to 90°C, max 10bar at 130°C)

When used with air Max 20bar up to 110°C, max 10bar at 130°C

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +130°C

● Suitable for: air, -10°C to +130°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

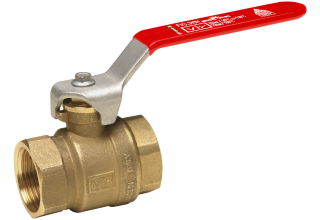

Manual Ball Valves - Fig. 330

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN100 - 4"

Threaded F/F (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

O-ring + adjustable packing

With handle or butterfly (up to DN≤50)

ACS and TR CU 010 compliant

PN25 (when used with air PN16 for DN≤50, PN10 for DN≥65)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +95°C

● Suitable for: air, -10°C to +110°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 333

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN050 - 2"

Threaded M/F (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

O-ring + adjustable packing

With handle or butterfly

ACS and TR CU 010 compliant

PN25 (PN16 when used with air)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +95°C

● Suitable for: air, -10°C to +110°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 338

Full bore brass ball valve

Diameters from DN010 - ⅜" to DN050 - 2"

Threaded M/M (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

O-ring + adjustable packing

With handle or butterfly

ACS and TR CU 010 compliant

PN25 (PN16 when used with air)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +95°C

● Suitable for: air, -10°C to +110°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

Manual Ball Valves - Fig. 332

Full bore brass ball valve with drain

Diameters from DN015 - ½" to DN050 - 2"

Threaded F/F (ISO 228/1)

Air testing according to EN12266-1

Blow-out proof stem

O-ring + adjustable packing

With handle or butterfly

ACS compliant

PN25 (PN16 when used with air)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +95°C

● Suitable for: air, -10°C to +110°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

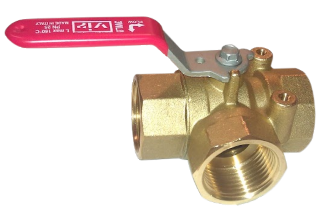

Manual Ball Valves - Fig. 3WT/3WL

Reduced bore 3-way brass ball valve

Diameters from DN010 - ⅜" to DN080 - 3"

Threaded F/F/F (ISO 228/1)

2 seat sealing

Blow-out proof stem

Available in the following versions:

● with "L" machined ball

● with "T" machined ball

PN25

For DN≤50 (Max 25bar up to 95°C, max 16bar with air or above 95°C)

For DN≥65 (Max 25bar up to 95°C, max 10bar with air or above 95°C)

Free of CE marking (cat. according to Art. 4.3 Dir. 2014/68/EU)

Working conditions

● Suitable for: water, 0°C to +150°C

● Suitable for: air, -10°C to +150°C

● Not suitable for: gases and liquids group 1 (Dir. 2014/68/UE)

huge selection with great pricing on all Manual Ball Valves / Manual C276 Ball Valves Suppliers in India, Manual Ball Valves Suppliers in India

Industrials Valves Dealers & Distributors in India | Industrial ball valves manufactured to your requirements. Mail us today!

Manual Ball Valves Recent Price List 2017-18

Manual Ball Valves Price

FOB Price: US $11-480.0 / Piece

|

Types of Ball Valves • Inline Ball Valves 2 Piece Valves |

• Water Thief Valves |

Ball Valves Ready Stock Available

Project Reference :

PROJECT |

YEAR |

Project : Water treatment plant at Malawi, AFRICA. |

1984 |

Project : Ambatale Raw Water Intake Pump Station, SRILANKA. |

1985 |

Project : Synthetic Fibre Plant, INDONESIA. |

1991 |

Project : Water Treatment Plant for Phoenix-II Paper plant, THAILAND. |

1992 |

Petron Civil Engineering Ltd., Bombay |

1992 |

Project : Water Supply Project, MAURITIUS. |

|

Paharpur Cooling Towers Ltd., Calcutta Project : National Petrochemical Co., IRAN |

1993 |

Ion Exchange India Ltd., Project: In INDONESIA |

1993 |

GEPL Holdings Pte. Ltd., SINGAPORE. Project : In PAKISTAN |

1997 |

UEM Inc., USA |

1998 |

Project: Shah Alam Sewage treatment plant, MALAYSIA |

|

Environmental Engineering Services (Asia)Pte. Ltd., Singapore. |

1999 |

Project : Taman Plangi Indah Phase-1 Sewage Treatment Plant, MALAYSIA. |

|

Gulfar Engineering & Contracting LLC, OMAN. |

2000 |

Risterm Negoce SA, Belgium. |

2004 |

Saudi Berkefeld Filter Co. Ltd., Riyadh, Saudi Arabia Project : Al-Qurayat SWT and Rafha wastewater treatment Plant, SAUDI ARABIA |

2004 |

Metax Engineering Corporation, Singapore |

2004 |

A. K. Almoayed Group WLL, Baharain |

2004 |

Satria Damai SDN BHD, Malaysia Project : SMART, MALAYSIA. |

2004 |

Risterm Negoce, Belgium |

2004 |

AVM International Ltd. A/S, Norway Project : Yapisal Erzurum, TURKEY |

2005 |

Stealth valve & Controls Ltd., Canada |

2005 |

Comfort Rich Enterprises Limited , Hongkong |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

Degremont., |

2005 |

Stealth valve & Controls Ltd., Canada |

2005 |

Metax Engineering Corporation Limited, Singapore. Project – Tuas pumping station of PUB, SINGAPORE |

2006 |

UEM India Limited, N. Delhi, Project : Pig farm project, MEXICO |

2006 |

AVM International Limited, Norway Project : Water treatment plant, GHANA |

2006 |

Spaans Babcock Limited, England, Project :- Liandysul WWTW |

2006 |

Comfort Rich Enterprises Limited, Hong Kong, Project : Shatin project, HONGKONG |

2006 |

ROFI UK Ltd. UK for Fluor AMEC LLC , Project : Nasiriya Water Project, IRAQ. |

2006 |

Kruger A/S Denmark. |

2006 |

Perrier Sorem, France, Project: - Paul Bert, FRANCE. |

2007 |

Ebara Corporation Japan, |

2007 |

Environmental engineering Services, Oman, |

2007 |

The National Co. For Mech. & Elect. Works Ltd., Kuwait Project: MPW – Construction of A4 Pumping Station, KUWAIT, Contract SE/69 |

2007 |

Aqua Tech International, Oman, / Contractors Technical Services Co. LLC, Oman. |

2007 |

Shutte GmbH, Germany CONSULTANTS : UHDE, Germany |

2007 |

Paramount Limited, Baroda |

2007 |

Syl Mac International, Mumbai. |

2007 |

A. K. Almoayed Group WLL, Baharain, |

2007 |

A. K. Almoayed Group WLL, Baharain, |

2007 |

Comfort Rich Enterprises Limited, Hong Kong, Project : Tai Po project , HONGKONG |

2007 |

Perrier Sorem, France, |

2007 |

Comfort Rich, Hong Kong. |

2007 |

Spanns Babcock, U.K. |

2007 |

Comfort Rich Supplies Co., Ltd, Hong Kong. |

2007 |

Syl Mac International, Mumbai. Project : HONG KONG |

2007 |

Project : Cheung Sha catchwater, HONG KONG. |

2007 |

Ryoden Engineering Co., Ltd., Hong Kong. |

2008 |

Ryoden Engineering Co., Ltd., Hong Kong. |

2008 |

Comfort Rich Supplies Co., Ltd, Hong Kong. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : Punggol Serangoon PS, Intake Structure & Ancillary Works, SINGAPORE. |

2008 |

Comfort Rich Supplies Co., Ltd, Hong Kong. Project : Shatin Storm water PS. HONG KONG. |

2008 |

WB Engineering & Consultancy Pte. Ltd., CHINA. Project : ULU Pandan Tidal gate, SINGAPORE. CONSULTANTS : |

2008 |

Star Steel International LLC, Dubai Project : Rebar Mill, Dubai. |

2008 |

Project : Astana Water Supply and Sewerage Project KAZAKHSTAN. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : Punggol Serangoon PS, Intake Structure & Ancillary Works, SINGAPORE. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : SINGAPORE. |

2008 |

Dutco Tennant LLC, Dubai |

2008 |

Dutco Tennant LLC, Dubai |

2008 |

Ebara Corporation Japan, |

2008 |

A.K. Almoayed Group WLL, Baharain, Project : A1 Pumping Station, BAHRAIN Al Hassanain mechanical Co., |

2008 |

Degremont Limited, Gurgaon, India |

2008 |

Global Engineering Systems FZ, Sharjah, UAE Project: - |

2009 |

Comfort Rich Supplies Co., Ltd, Hong Kong. Project: Ma On Shan SPS, HONG KONG CONSULTANTS : |

2009 |

Kharafi National KSC (Closed), Kuwait |

2009 |

Kharafi National KSC (Closed), Kuwait |

2009 |

Spanns Babcock Ltd., U.K. |

2009 |

Spanns Babcock Ltd., U.K.. |

2009 |

Astra Marketing Limited, Bangkok, Thailand. |

2009 |

Gulf Petrochemical Services & Trdg. LLC, Oman |

2009 |

Lutz-Jesco Middle East FZE, Sharjah, U. A. E. Project: |

2009 |

PLS France for Degremont Ltd., France. |

2009 |

PVT Engineering SDN BHD, Malaysia Project: Kepala Batas, MALAYSIA CONSULTANTS : RPM Engineers SDN BHD |

2009 |

WB Engineering & Consultancy Pte. Ltd., China |

2009 |

Dutco Tennant LLC, Dubai |

2009 |

Are you looking for a reliable Manual Ball Valves dealer & distributor in below countries:

Origin: Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin