About Us

Citizen Valves supplies ball, butterfly, gate, globe, check, plug valves in standards.specialized in industrial valve manufacturing and Exports

Ball Valve, Industrial Valve, Stainless Steel Valve Dealers, Globe Valves Distributors, Gate Valves Exporters, Needle Valve Dealers / Distributors / Exporters / Suppliers india, Plug Valve Manufacturers in india, Butterfly Valve Price in India

About Us

Citizen Valves, located in Mumbai, Maharashtra, INDIA, is established in 1981. With over 35 years' experience, Citizen Valve became professional valve manufacturer specialized in manufacturing, and Supplying Industrial valves, our factory in Gujarat covers an area of 15000 square meters equipped with latest & Automated Machinery.we also arrange our factory tour as per requirement of our customers,

The industrial valves we manufactured include gate valves, check valves, globe valves, ball valves, butterfly valves, plug valves, strainer in Alloy Steel , Carbon Steel & Stainless Steel. The valves are manufactured according to ANSI, API, DIN, GOST, BS, JIS standards and as per customer's special requirements. currently we are exporting around 60 countries like Kingdom of Saudi Arabia, UAE, Kuwait, Oman, Turkey, Egypt, Bahrain, Indonesia, Singapore, Malaysia, Russia, Australia, New Zealand and many, our Industrial valves are more suitable for a wide variety of applications in the Gas, Oil, Refining, Chemical, Marine, Power Generation and Pipeline Transmission Industries.

Industrial valves

Industrial valves Suppliers

Pressure range: Class 150 – Class 2500, PN6 - PN420.

Size range: NPS 1/2 - 48

Inches.

Operation type: manual, gearbox, chain wheel, pneumatic, electric, etc.

Connection End: flanged, BW, SW, NPT, wafer type, etc.

Materials (casting):

WCB, WCC, LCB, LCC, LC1 - 3, CF8, CF3, CF8M, CF3M, CF8C, CN7M, CA15, C5, WC5, WC6, WC9,

Monel, etc.

Materials (forging): A105, LF1, LF2, F304, F304L, F316, F316L, F11,

F22, F6, F51, F316H, F321, F347, Inconel, etc.

Citizen Valves have got the

approval of ISO 9001, API 6D, CE and ISO 14001,OHSAS 18001 certification. Citizen Valves

established a multi-functional phys-chemical lab to supervise the quality further from

time to time and fitted out spectrum analyzer, material tester, impact tester, hardness

meter, tensile tester, thickness meter, magnetic particle tester, fugitive emission

tester, and NDE testing equipment.

The primary target of Citizen Valves is to

offer products and services of high quality, so that we will receive the highest degree

of Customer satisfaction,

Our Specialisation:

Cast Steel Gate Valves: API 600, API 6D, JIS B2073, JIS B2083,

Carbon, Stainless, Alloy Steel, BW or Flanged, 150 - 2500 LB, 1/2 - 48 inch. or as

required.

Valves Testing

CITIZEN Valves has a specialist in-house dedicated testing facility. In addition to routine hydrostatic and gas pressure tests, we are also able to perform Cryogenic tests to BS6364 and Emission testing to ISO 15848. The CITIZEN Valves Testing Service is a niche service and is available to external customers as a standalone service.

Many of our products are for use under extreme conditions. We offer a sophisticated range of in-house testing to suit most end user requirements including:

- Low temperature testing down to as low as -196°C;

- Elevated temperature testing up to 700°C;

- Emission Leak Detection 77/312 Mass Spectrometer;

- Vaccum Testing 77/308;

- Dye Penetrant Examination for detecting surface defects in casting, forging and welding;

- Ferrite Testing;

- Positive Material Identification;

- Prototype Testing;

- API598 Hydrostatic BS EN 12266 levels 1 & 2.

Testing is carried out during mechanical operation for accurate results.

Emissions Performance Testing is a key area of growth for our business as a result of rising pressure from Governments and 'green thinking' societies for businesses to operate as environmentally friendly as possible. Testing is offered in accordance with ISO 15848 and is carried out at cyclic temperatures and pressures that cover the valves full range of service conditions whilst mechanically operating. This enables us to accurately qualify the performance of packings and gaskets in their actual environment prior to dispatch to ensure we provide clients with high performance high integrity valves that last.Manufacturing

Having over 35 years of designing and manufacturing a CITIZEN Valve, our CITIZEN product range continues to become a preferred choice of our Customers and End Users. Over recent years our range of product has increased offering a product range suitable for general purpose applications as well as continuing to provide and develop a ‘tailored’ valve to work within critical service applications.

All of the materials selected for our CITIZEN Product are sourced through approved suppliers who must complete CITIZEN Valves Quality Service Test which is based on the British Standard ISO9001. Upon receipt all materials are inspected for compliance.

All of our critical service valves are manufactured on castings sourced from either the India, UK, Europe and the USA and are fully complaint and certified to International standards.

For general service and none critical applications we can offer a CITIZEN Valve with either India, Korean or Chinese origin. All these valves are manufactured under the same control we adopt within our India facilities and are certified by CITIZEN Valves but can offer a more economical valve supply solution.

Our manufacturing range includes gate valves to API 600/ISO 10434, globe valves to BS1873 'T', 'L' and 'Y' patterns and swing check valves to BS 1868 or API 6D regular. All the products designed are in compliance with ASME B16.34 and the PED. We are regularly asked to produce high integrity valves for corrosive or hazardous duty to the standard of ASTM E446 levels 3, 2 and 1, depending on the criticality of the application.

Our standard production sizes for our gate, globe, check, NRV, Butterfly valves range from 15mm up to 1500mm although we also offer a ‘bespoke’ service where we can produce customised exotic valves designed to meet clients' specific requirements. The synergy between our stocking and manufacturing businesses means shorter lead times for our clients and we are able to efficiently dispatch our products worldwide.

We are proud of our CITIZEN Product maintains the acceptance of Shell, BP, Exxon, Mobil, Ineos, Chevron, Sasol and Conoco-Philips and Sinopec to name a few.

CHECK OUR PRODUCTS GALLERY

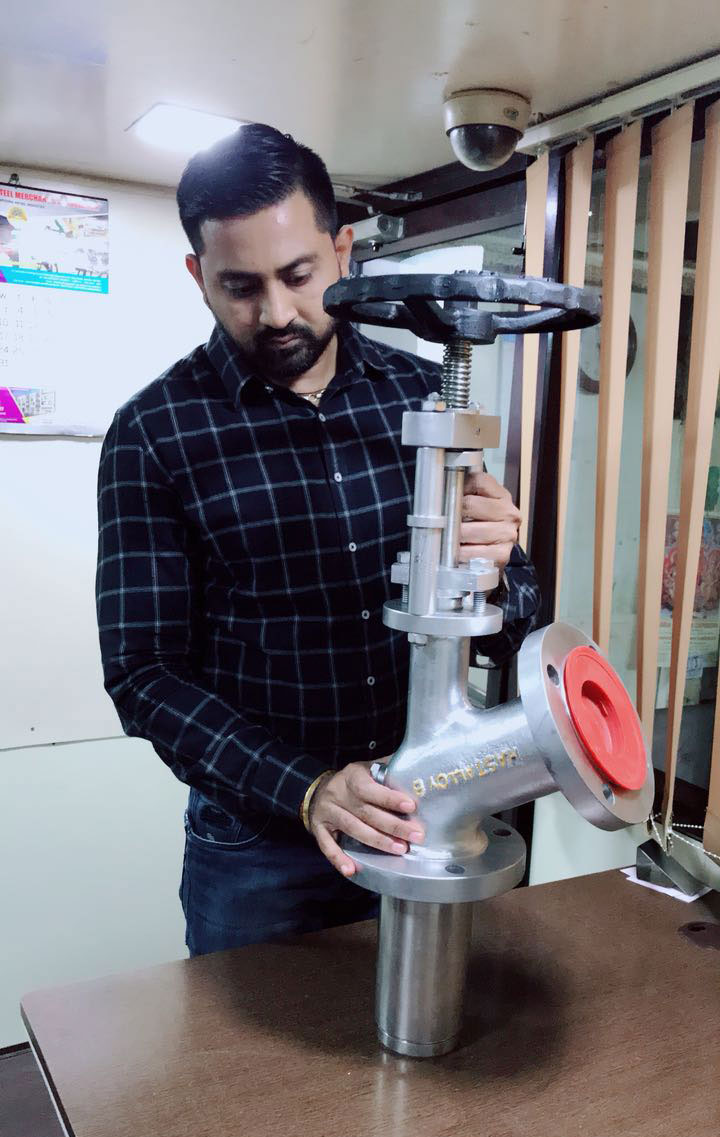

Hastelloy - B Flush Bottam Valve 3" × 150 RF Type ( Final Inspection Picture ) Export to Turkey |

||

|

|

|

|

|

|

|

||

Check our price of Industrial Valves:

API Check Valve Price in India

API Check Valves: API 594, API 6D, API 602, BS 1868, BS 1873, ASME B16.34, Cast/ Forged Steel, Swing, Lift, Wafer, Class 150 - 2500, 1/2 - 48 inch.

DIN Check Valve Price in India

DIN 3840, BS EN 1868, Cast, Forged, Alloy, Carbon, Stainless Steel, Swing, Lift, Wafer, BW, Flanged Ends, PN 16 - 100, DN 40 - 900.

Trunnion Ball Valves price in India

Trunnion Mounted Ball Valves: API 608, API 6D Cast / Forged Steel, Full & Reduced Bore, Side Entry, Two / Three-piece, Class 150 - 2500, 2 - 40 inch.

Metal Seated Ball Valve Price In India

API 6D, Cast / Forged, Carbon, Stainless, Alloy, Duplex Steel, Metal to Metal Seat &

Ball, Class 150 - 1500, 1/2 - 24 inch.

Top Entry Ball Valve Price List

API 6D, ASME B16.34, Floating / Trunnion Mounted, Full / Reduced Bore, Double Block &

Bleed, Class 150 - 2500, 2 - 24 inch.

Fully Welded Ball Valve Price in Australia

API 6D, Forged Steel, Full / Reduced Bore, Optional double piston, extended stem design,

Class 150 - 2500, 2 - 48 inch.

Floating Ball Valve Price in New Zealand

Floating Ball Valves: API 608, API 6D, BS 5351 Cast / Forged Steel, Full / Reduced Bore,

Two-piece, Flanged / BW, Class 150 - 2500, 1/2 - 10 inch.

Four Way Ball Valves cost

Three Way Ball Valves Latest price List

Three way ball valve can be divided in to L type and T type. L type three way ball valve

is used to change the flow direction and connect mutually perpendicular two pipelines. T

type three way ball valve is utilized to divert, interflow and flow reversal, which can

connect three pipelines or two pipelines.

API Globe Valve Price:

API Globe Valves: BS 1873, ASME B16.34, API 602, Cast, Forged Steel, Bellow sealed, BW,

Flanged Ends, Rising Stem, Class 150 - 2500, 1/2 - 30 inch.