Floating Ball Valves Manufacturers / Suppliers

stainless steel Floating Ball Valve Suppliers, Alloy Steel Floating Ball Valve Exporters, Duplex Steel Floating Ball Valve, Carbon Steel Floating Ball Valve India

All Types Floating Ball Valves Suppliers, All Size Floating Ball Valves Suppliers in India, All Top Brands Floating Ball Valves Dealer in India, Floating Gas Ball Valves, Floating Ball Valves for Oil Industry, Floating Ball Valves for Water, Industrial Floating Ball Valves

Floating Ball Valves Suppliers Dealers Distributors Exporters in India

Citizen Valves has extensive experience in manufacturing Trunnion Mounted, Side & Top Entry Ball Valves, both Soft and Metal Seated.

stainless steel Floating Ball Valve, Alloy Steel Floating Ball Valve, Duplex Steel Floating Ball Valve, Carbon Steel Floating Ball Valve

Class 150 Floating Ball Valve, Class 300 Floating Ball Valve, Class 400 Floating Ball Valve, Class 600 Floating Ball Valve, Class 900 Floating Ball Valve, Class 1500 Floating Ball Valve, API 600 Floating Ball Valve

A105 Floating Ball Valves, A182 F304 Floating Ball Valves, F3304L Floating Ball Valves, F316 Floating Ball Valves, F316L Floating Ball Valves, A182 F51 Floating Ball Valves, F53 Floating Ball Valves, A350 LF2 Floating Ball Valves, LF3 Floating Ball Valves, LF5 Floating Ball Valves, API 6D Floating Ball Valves, API 608 Floating Ball Valves, ISO 17292 Floating Ball Valves, API 6FA Floating Ball Valves, API 607 Floating Ball Valves, API 598 Floating Ball Valves

Floating ball valves are more than just floating ball valves

Floating ball valves are usually considered to be a simple type of valve and are not, in fact, particularly appreciated. When one talks about floating ball valves, most people think of a valve with fixed seats and a floating balls usually smaller valves inrelatively low pressures systems.

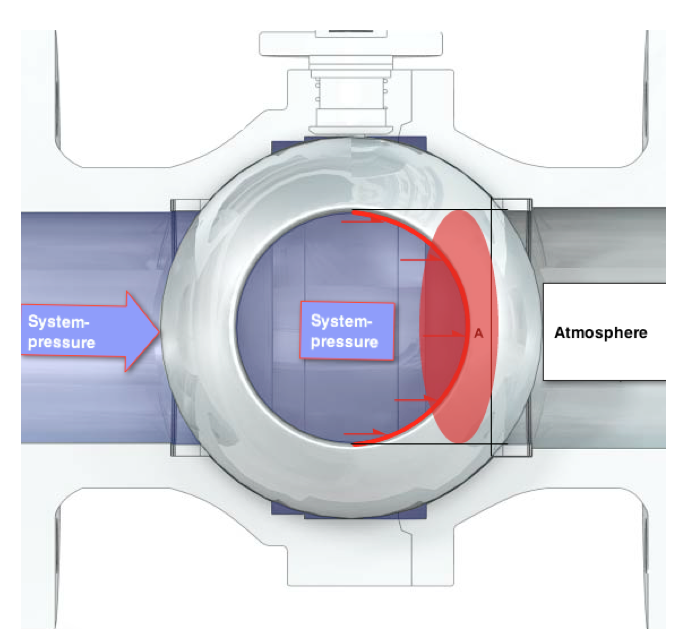

However, when it comes to tightness, floating ball valves are mor reliable than trunnion ball valves. The reason is that in floating ball valves, unlike in trunnion ball valves, the system pressure forces the entire ball against the downstream seat, see Image In trunnion ball valves the pressure usually force the upstream seat against the ball and hence they depend on seats that can be locked in the seat pocket due to various impurities.

Since it is t e force from the system pressure acting against the entire surface of the external seat diameter that gives the sealing force to the floating ball valve, its sealing force is much stronger, in relative terms, than that of a trunnion ball valve. This is also one of the drawbacks of this kind of ball valve – it can be difficult to open with a differential pressure. Another advantage of the floating ball valve, as compared to the trunnion ball valve, is that the former is better suited for opening with differential pressure. This due to the fact that the main seal in a floating ball valve are against the downstream seat. When a ball valve is opened with differential pressure, the damage from erosion/cavitation will always be inflicted on the upstream seat because this is where the highest pressure drop is recorded. Thus, in a trunnion ball valve it is the main se al of the valve that gets the damage when opening with differential pressure. This is the basic principle of a floating ball valve, but, as the title says, there is more to this type of valve than most people think.

e force from the system pressure acting against the entire surface of the external seat diameter that gives the sealing force to the floating ball valve, its sealing force is much stronger, in relative terms, than that of a trunnion ball valve. This is also one of the drawbacks of this kind of ball valve – it can be difficult to open with a differential pressure. Another advantage of the floating ball valve, as compared to the trunnion ball valve, is that the former is better suited for opening with differential pressure. This due to the fact that the main seal in a floating ball valve are against the downstream seat. When a ball valve is opened with differential pressure, the damage from erosion/cavitation will always be inflicted on the upstream seat because this is where the highest pressure drop is recorded. Thus, in a trunnion ball valve it is the main se al of the valve that gets the damage when opening with differential pressure. This is the basic principle of a floating ball valve, but, as the title says, there is more to this type of valve than most people think.

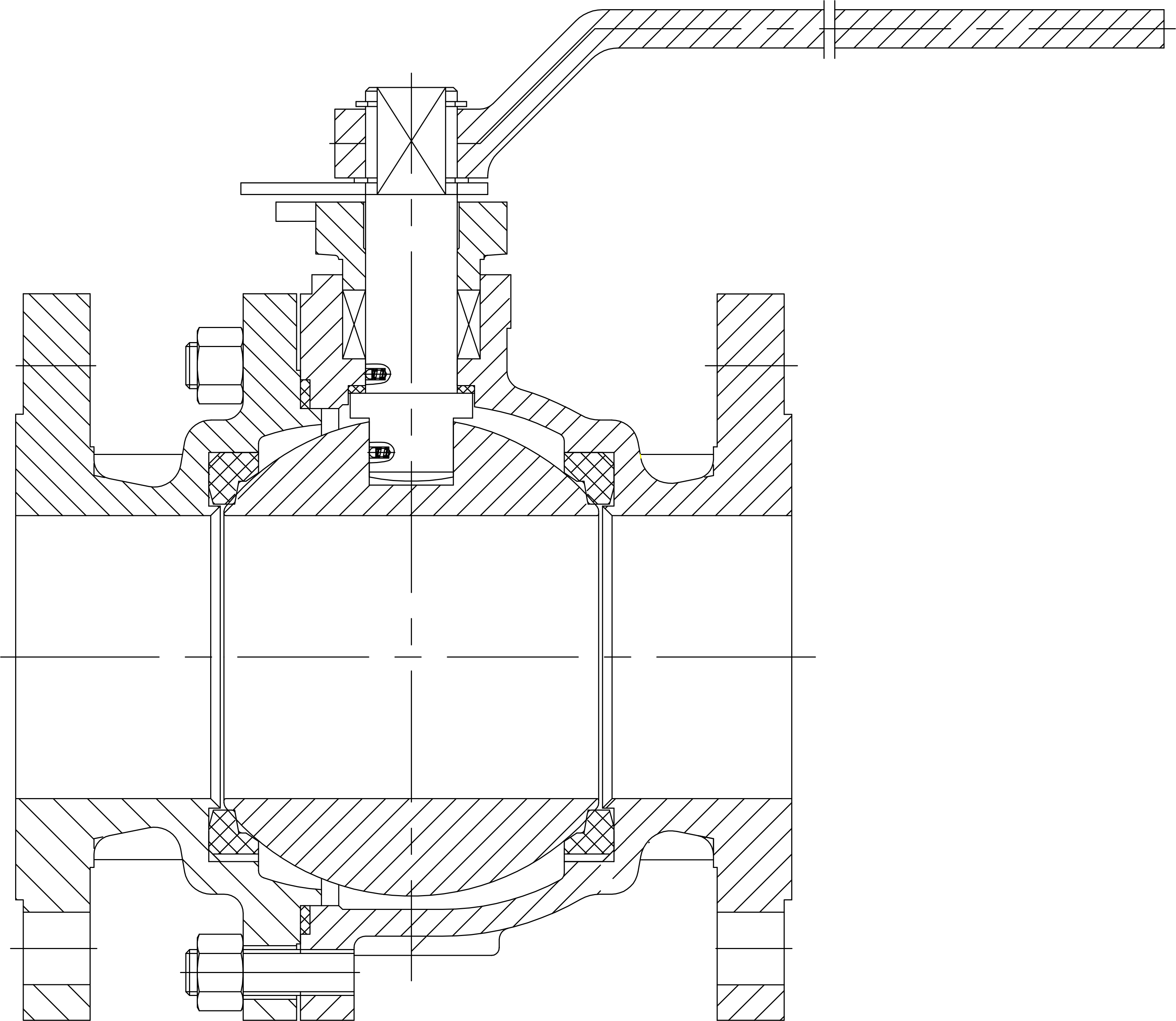

A comparison of the outer appearance of the valve body in fig. 1 and fig. 3 fails to show any significant differences. They are both split body having two-piecs bodies and RF flanges. However, if we take a look on the inside of the valve body, at the shape of the seats, there is a major difference. The valve in fig. 3 has spring-loaded floating seats with radial seals. Both valves in fig. 1 and 3 are bi-directional with the downstream seat providing the main sealing function. The major difference is that in the case of the valve illustrated in fig. 3 double sealing can be achieved if the cavity is depressurized. The problem is that auxiliaryvalves are not usually fitted into the valve body, nor are there normally any holes where a auxiliary valve could be fitted so as to take advantage of all the possibilities available.

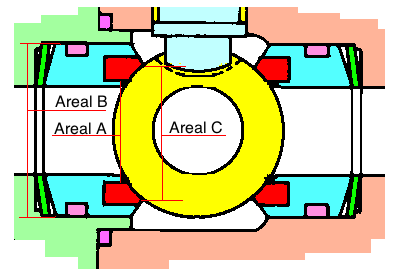

If the body was equipped with an auxiliary valve in to its cavity, it would be possible to depressurize the cavity once the valve is in the closed position. The valve would function just like a solid slab gate valve. Fig. 4 indicates the areas on which the system pressure will act.When the valve is in the closed position, the sealing force applied to the downstream seat is equal to the system pressure multiplied by the surface area marked C. When the cavity is depressurized, the sealing force applied to the downstream seat equals the system pressure multiplied by the surface area marked B. The sealing force applied to the downstream seat hence increases by 25-30%. Moreover, we also have a sealing force applied to the upstream seat, amounting to the force of the system pressure multiplied by the area between B and A. Once the valve is closed and the cavity depressurized, leave the valve for 15 minutes and check the upstream seat’s tightness. If the seat is tight, we have a double-sealing valve which is just as reliable as a blind flange. If the leaver or actuator is taken off, the valve cannot under any circumstances start to leak. We can easily agree with the fact that the valve is difficult to operate now, and sometimes there can be situations where we may need to equalize the pressure across the valve before operating the valve.

Optimize your process with the specific valve configuration that satisfies your needs

Each process in every industry is somewhat unique, including your processes. Our vast valve portfolio allows you to meet your unique process conditions and helps you achieve optimum results. By bringing together some of the preeminent floating ball valve brands, all of your process requirements can be fulfilled. Whether your process requires API 6D valves, API 608 valves, adjustable stem packing, O-ring stem seals, API 607 fire-safe rating, PTFE seats, carbon seats, or one of thousands of other configurations, we have the valve to help lower your cost and achieve maximum process uptime.

|

|

|

Floating Ball Valve

FBV floating ball valves are offered in 2 PC side entry, 3 PC side entry or welded body design in a wide range of carbon and stainless steel materials. FBV floating ball valves are manufactured according to API 6D or API 608 Design and fire tested per API 6FA and API 607 Standard.

Product Range:

Cast Steel Floating Ball Valve (1PC or 2 PC)

- Size: 1/2~10(DN15~DN250)

- Rating: 150~300LB(PN16~PN40)

- Body Materials: Cast Carbon Steel, Stainless Steel, Duplex Steel

- Trim: Carbon Steel, Stainless Steel, Duplex Steel

- Operation: Electric, Pneumatic, Hydraulic

- Sizes NPS 2 to NPS 8

- Class 150 to Class 2500

Forged Steel Floating Ball Valve (2PC or 3 PC)

- Size: 1/2~4(DN15~DN100)

- Rating: 150~2500LB(PN16~PN420)

- Body Materials: Forged Carbon Steel, Stainless Steel, Duplex Steel

- Trim: Carbon Steel, Stainless Steel, Duplex Steel

- Operation: Electric, Pneumatic, Hydraulic,

-

Ball Valve Products Range

- Material: Carbon Steel, Stainless, Duplex Steel, Bronze

- Size: 1/2"-56"

- Rating: Class 150, 300, 400, 600, 800, 900, 1500, 2500

- PN: PN16, P20, PN25, PN40, PN64, PN100, PN150, PN160, PN250, PN420

- Ends: Flanged, BW, Hub, SW, NPT

DESIGN FEATURES

- Full or Reduced Bore

- RF, RTJ, or BW

- Bolted bonnet or welded body design

- Anti-Static Device

- Anti-Blow out Stem

- Cryogenic or High Temperature, Extended Stem

- Full port or reduce port

- Fire safe design

- Blowout-proof stem

- Low emission control

- ALL with locking device

- ISO 5211 top flange

- Optional various actuator

floating ball valves include:

- Cast steel floating ball valve (1 PC or 2 PC)

- Forged steel floating ball valve(2 PC or 3 PC)

MATERIALS

Available Forging (A105, A182 F304, F3304L, F316, F316L, A182 F51, F53, A350 LF2, LF3, LF5) Casting (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A352 LCB, LCC, LC2, A995 4A. 5A), Inconel, Hastelloy, MonelDESIGN STANDARD

- Design & manufacture according to API 6D, API 608, ISO 17292

- Face-to-face according to API 6D, ASME B16.10 OR MFG’s standard

- End Connection according to ASME B16.5 (RF & RTJ), ASME B16.25 (BW)

- Test & inspection according to API 6D, API 598

- Fire safe design according to API 6FA, API 607

- Also available per NACE MR-0175, NACE MR-0103, ISO 15848

| SPECIFICATION | ||

|---|---|---|

| SIZE | 2" TO 18" | |

| CLASS | 150# / 300# / 400# / 600# / 900# / 1500# | |

| END | FLANGED / BUTT WELD | |

| STANDARD | API 6D / API 600 | |

| FIRE SAFE | API 6 FA | |

huge selection with great pricing on all Floating Ball Valves / Floating C276 Ball Valves Suppliers in India, stainless steel Floating Ball Valve Suppliers in India

Industrials Valves Dealers & Distributors in India | Industrial ball valves manufactured to your requirements. Mail us today!

Floating Ball Valves Recent Price List 2017-18

Floating Ball Valves Full Bore , ANSI Class 150 Price

FOB Price: US $1-460.0 / Piece

Floating Ball Valves Reduced Bore ANSI Class 300 Price

FOB Price: US $1-460.0 / Piece

3 Piece Ball Valves Reduce Bore , 2000/1500 psi Price

FOB Price: US $1-460.0 / Piece

|

Types of Ball Valves • Inline Ball Valves 2 Piece Valves |

• Water Thief Valves |

Ball Valves Ready Stock Available

Project Reference :

PROJECT |

YEAR |

Project : Water treatment plant at Malawi, AFRICA. |

1984 |

Project : Ambatale Raw Water Intake Pump Station, SRILANKA. |

1985 |

Project : Synthetic Fibre Plant, INDONESIA. |

1991 |

Project : Water Treatment Plant for Phoenix-II Paper plant, THAILAND. |

1992 |

Petron Civil Engineering Ltd., Bombay |

1992 |

Project : Water Supply Project, MAURITIUS. |

|

Paharpur Cooling Towers Ltd., Calcutta Project : National Petrochemical Co., IRAN |

1993 |

Ion Exchange India Ltd., Project: In INDONESIA |

1993 |

GEPL Holdings Pte. Ltd., SINGAPORE. Project : In PAKISTAN |

1997 |

UEM Inc., USA |

1998 |

Project: Shah Alam Sewage treatment plant, MALAYSIA |

|

Environmental Engineering Services (Asia)Pte. Ltd., Singapore. |

1999 |

Project : Taman Plangi Indah Phase-1 Sewage Treatment Plant, MALAYSIA. |

|

Gulfar Engineering & Contracting LLC, OMAN. |

2000 |

Risterm Negoce SA, Belgium. |

2004 |

Saudi Berkefeld Filter Co. Ltd., Riyadh, Saudi Arabia Project : Al-Qurayat SWT and Rafha wastewater treatment Plant, SAUDI ARABIA |

2004 |

Metax Engineering Corporation, Singapore |

2004 |

A. K. Almoayed Group WLL, Baharain |

2004 |

Satria Damai SDN BHD, Malaysia Project : SMART, MALAYSIA. |

2004 |

Risterm Negoce, Belgium |

2004 |

AVM International Ltd. A/S, Norway Project : Yapisal Erzurum, TURKEY |

2005 |

Stealth valve & Controls Ltd., Canada |

2005 |

Comfort Rich Enterprises Limited , Hongkong |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

ROFI UK Ltd./ Syl-Mac International |

2005 |

Degremont., |

2005 |

Stealth valve & Controls Ltd., Canada |

2005 |

Metax Engineering Corporation Limited, Singapore. Project – Tuas pumping station of PUB, SINGAPORE |

2006 |

UEM India Limited, N. Delhi, Project : Pig farm project, MEXICO |

2006 |

AVM International Limited, Norway Project : Water treatment plant, GHANA |

2006 |

Spaans Babcock Limited, England, Project :- Liandysul WWTW |

2006 |

Comfort Rich Enterprises Limited, Hong Kong, Project : Shatin project, HONGKONG |

2006 |

ROFI UK Ltd. UK for Fluor AMEC LLC , Project : Nasiriya Water Project, IRAQ. |

2006 |

Kruger A/S Denmark. |

2006 |

Perrier Sorem, France, Project: - Paul Bert, FRANCE. |

2007 |

Ebara Corporation Japan, |

2007 |

Environmental engineering Services, Oman, |

2007 |

The National Co. For Mech. & Elect. Works Ltd., Kuwait Project: MPW – Construction of A4 Pumping Station, KUWAIT, Contract SE/69 |

2007 |

Aqua Tech International, Oman, / Contractors Technical Services Co. LLC, Oman. |

2007 |

Shutte GmbH, Germany CONSULTANTS : UHDE, Germany |

2007 |

Paramount Limited, Baroda |

2007 |

Syl Mac International, Mumbai. |

2007 |

A. K. Almoayed Group WLL, Baharain, |

2007 |

A. K. Almoayed Group WLL, Baharain, |

2007 |

Comfort Rich Enterprises Limited, Hong Kong, Project : Tai Po project , HONGKONG |

2007 |

Perrier Sorem, France, |

2007 |

Comfort Rich, Hong Kong. |

2007 |

Spanns Babcock, U.K. |

2007 |

Comfort Rich Supplies Co., Ltd, Hong Kong. |

2007 |

Syl Mac International, Mumbai. Project : HONG KONG |

2007 |

Project : Cheung Sha catchwater, HONG KONG. |

2007 |

Ryoden Engineering Co., Ltd., Hong Kong. |

2008 |

Ryoden Engineering Co., Ltd., Hong Kong. |

2008 |

Comfort Rich Supplies Co., Ltd, Hong Kong. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : Punggol Serangoon PS, Intake Structure & Ancillary Works, SINGAPORE. |

2008 |

Comfort Rich Supplies Co., Ltd, Hong Kong. Project : Shatin Storm water PS. HONG KONG. |

2008 |

WB Engineering & Consultancy Pte. Ltd., CHINA. Project : ULU Pandan Tidal gate, SINGAPORE. CONSULTANTS : |

2008 |

Star Steel International LLC, Dubai Project : Rebar Mill, Dubai. |

2008 |

Project : Astana Water Supply and Sewerage Project KAZAKHSTAN. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : Punggol Serangoon PS, Intake Structure & Ancillary Works, SINGAPORE. |

2008 |

WB Engineering & Consultancy Pte. Ltd., China Project : SINGAPORE. |

2008 |

Dutco Tennant LLC, Dubai |

2008 |

Dutco Tennant LLC, Dubai |

2008 |

Ebara Corporation Japan, |

2008 |

A.K. Almoayed Group WLL, Baharain, Project : A1 Pumping Station, BAHRAIN Al Hassanain mechanical Co., |

2008 |

Degremont Limited, Gurgaon, India |

2008 |

Global Engineering Systems FZ, Sharjah, UAE Project: - |

2009 |

Comfort Rich Supplies Co., Ltd, Hong Kong. Project: Ma On Shan SPS, HONG KONG CONSULTANTS : |

2009 |

Kharafi National KSC (Closed), Kuwait |

2009 |

Kharafi National KSC (Closed), Kuwait |

2009 |

Spanns Babcock Ltd., U.K. |

2009 |

Spanns Babcock Ltd., U.K.. |

2009 |

Astra Marketing Limited, Bangkok, Thailand. |

2009 |

Gulf Petrochemical Services & Trdg. LLC, Oman |

2009 |

Lutz-Jesco Middle East FZE, Sharjah, U. A. E. Project: |

2009 |

PLS France for Degremont Ltd., France. |

2009 |

PVT Engineering SDN BHD, Malaysia Project: Kepala Batas, MALAYSIA CONSULTANTS : RPM Engineers SDN BHD |

2009 |

WB Engineering & Consultancy Pte. Ltd., China |

2009 |

Dutco Tennant LLC, Dubai |

2009 |

Are you looking for a reliable Floating Ball Valves dealer & distributor in below countries:

Origin: Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin